With the idea of a grid of printers moving on a larger plane in mind, we set out to design and build a proof of concept using the tools at our disposal and be able to show you it can be done.

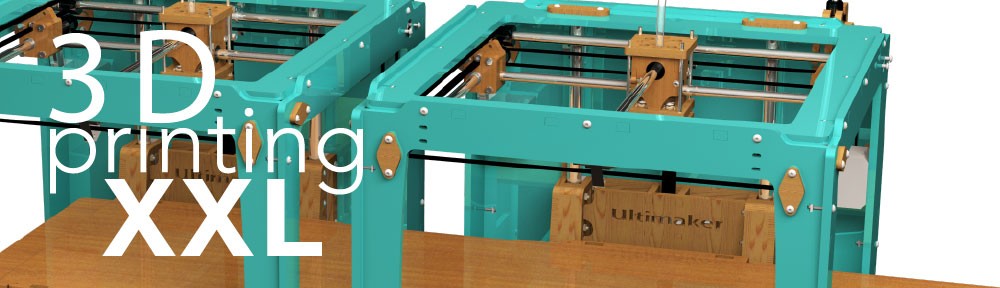

We decided to simplify the issue by only using two printers moving on only 1 axis as the first step. The standard Ultimakers conveniently have holes in the side, through which we could fit a large table, thus simulating the large axis movement in one direction without massively altering the printers itself. Only the addition of a single control motor for the new bed will be required and the 3D machines can be placed side by side and otherwise operate normally.

Other requirements and problems which are similar to the main concept is the splicing of the 3d model into several different files for each printer to extrude it’s section. As an addition to that the section in the blind spot of the printers needs to be coded and placed in the proper order to create one continuous piece.

Other requirements and problems which are similar to the main concept is the splicing of the 3d model into several different files for each printer to extrude it’s section. As an addition to that the section in the blind spot of the printers needs to be coded and placed in the proper order to create one continuous piece.

We’ll keep you posted on our progress!