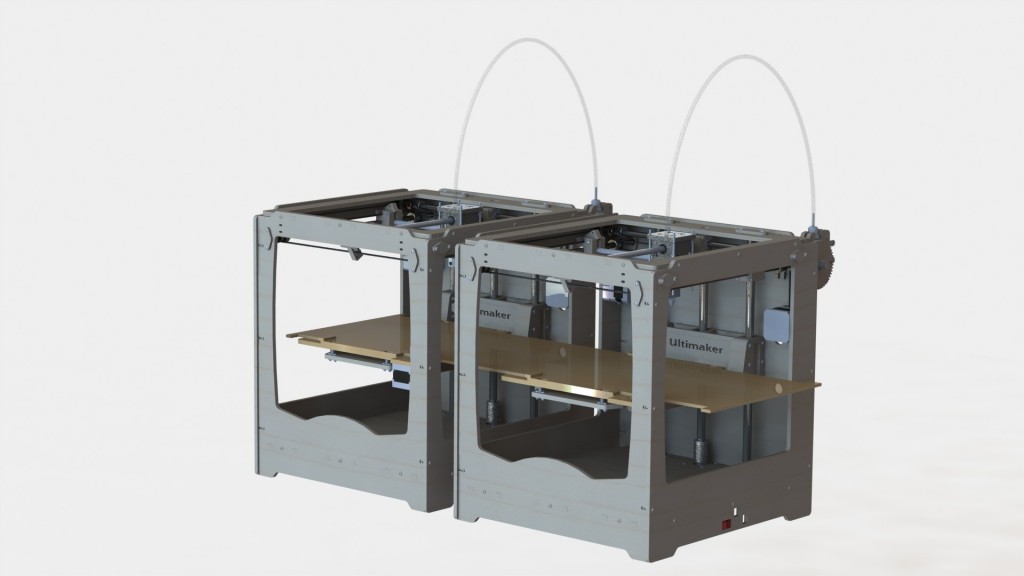

In this project we will try to make big and detailed models fast by using multiple smaller 3d-printers connected to each other. This means we will have to devide the model in several smaller pieces; each one small enough to be printed by one ultimaker. Because there will always be space between the printable area’s of the printers the model needs to be moved so that the gaps can be filled. This needs to happen between the printing of every layer.

For this project we will start small, with two printers connected to each other. At first we will use the table of the ultimakers themselves for the movement in z-direction. We will lay a table on top of it that can be moved in one direction (x or y). After both ultimakers have finished printing their part of the first layer, the table with the model is moved so the gap between the printed parts can be printed also. Then the table is moved back and the second layer is printed the same way.

Normally a model is converted to an stl file which is then converted to G-code. The G-code contains the instructions for the printer. The G-code must be altered in such a way that the model is split into parts and the different printers all get their x and y movement instructions. The coördiates need to be corrected for when we move the model on our table.

Normally a model is converted to an stl file which is then converted to G-code. The G-code contains the instructions for the printer. The G-code must be altered in such a way that the model is split into parts and the different printers all get their x and y movement instructions. The coördiates need to be corrected for when we move the model on our table.

We will be testig this principle on a single Ultimaker by altering the G-code so that the printer will print the first layer of let’s say the left half, stops, prints the first layer of the right half, stops, move the table down, prints the second layer of the left half….. and so on.

Inevitably there will be some sort of seam between the halves. We will look at the appereance of this seam and test it on strenght.